84.57 CENTROS DE MECANIZADO, MAQUINAS DE PUESTO FIJO Y MAQUINAS DE PUESTOS MULTIPLES, PARA TRABAJAR METAL.

Según la Nota 4 c) del Capítulo, esta partida no comprende las líneas o cadenas de transferencia compuestas de diferentes máquinas unidas entre sí por un transportador que traslada las piezas.

De acuerdo con las disposiciones de la Nota mencionada, no se clasifican en la presente partida, los “talleres flexibles”, que están constituidos por varias máquinas, generalmente de control numérico, o por varios grupos de máquinas, así como los sistemas de manipulación automática constituidos por pórticos, carretillas transportadoras sin conductor, manipuladores, robotes industriales, por ejemplo, para alimentar las máquinas o desplazar las piezas después del mecanizado. Los diferentes grupos de máquinas y los sistemas de manipulación que constituyen el ”taller flexible“ están regidos por máquinas para tratamiento de información.

OMA INGLES: In accordance with Chapter Note 4 (c) this heading does not cover transfer lines consisting of various machines linked by a conveyor carrying the workpieces.

Under the terms of the above-mentioned Chapter Note, this heading also excludes " flexible manufacturing systems " (FMS) which consist of several machines, generally numerically controlled, or several groups of machines, together with

facilities which constitute the flexible manufacturing system are controlled by automatic data processing machines.

FLEXIBLE MANUFACTURING SYSTEMS (FMS)

Introduction

In the middle of the 1960s, market competition became more intense.

During 1960 to 1970 cost was the primary concern. Later quality became a priority. As the market became more and more complex, speed of delivery became something customer also needed.

A new strategy was formulated: Customizability. The companies have to adapt to the environment in which they operate, to be more flexible in their operations and to satisfy different market segments (customizability).

Thus the innovation of FMS became related to the effort of gaining competitive advantage.

First of all, FMS is a manufacturing technology.

Secondly, FMS is a philosophy. "System" is the key word. Philosophically, FMS incorporates a system view of manufacturing. The buzz word for today’s manufacturer is "agility". An agile manufacturer is one who is the fastest to the market, operates with the lowest total cost and has the greatest ability to "delight" its customers. FMS is simply one way that manufacturers are able to achieve this agility.

An MIT study on competitiveness pointed out that American companies spent twice as much on product innovation as they did on process innovation. Germans and Japanese did just the opposite.

In studying FMS, we need to keep in mind what Peter Drucker said: "We must become managers of technology not merely users of technology".

Since FMS is a technology, well adjusted to the environmental needs, we have to manage it successfully.

1. Flexibility concept. Different approaches

Today flexibility means to produce reasonably priced customized products of high quality that can be quickly delivered to customers.

So, what is flexibility in manufacturing?

While variations abound in what specifically constitutes flexibility, there is a general consensus about the core elements. There are three levels of manufacturing flexibility.

(a) Basic flexibilities

Machine flexibility - the ease with which a machine can process various operations

Material handling flexibility - a measure of the ease with which different part types can be transported and properly positioned at the various machine tools in a system

Operation flexibility - a measure of the ease with which alternative operation sequences can be used for processing a part type

(b) System flexibilities

Volume flexibility - a measure of a system’s capability to be operated profitably at different volumes of the existing part types

Expansion flexibility - the ability to build a system and expand it incrementally

Routing flexibility - a measure of the alternative paths that a part can effectively follow through a system for a given process plan

Process flexibility - a measure of the volume of the set of part types that a system can produce without incurring any setup

Product flexibility - the volume of the set of part types that can be manufactured in a system with minor setup

(c) Aggregate flexibilities

Program flexibility - the ability of a system to run for reasonably long periods without external intervention

Production flexibility - the volume of the set of part types that a system can produce without major investment in capital equipment

Market flexibility - the ability of a system to efficiently adapt to changing market conditions

2. Seeking benefits on flexibility

Today’s manufacturing strategy is to seek benefits from flexibility. This is only feasible when a production system is under complete control of FMS technology. Having in mind the Process- Product Matrix you may realize that for an industry it is possible to reach for high flexibility by making innovative technical and organizational efforts. See the Volvo’s process structure that makes cars on movable pallets, rather than an assembly line. The process gains in flexibility. Also, the Volvo system has more flexibility because it uses multi-skill operators who are not paced by a mechanical line.

So we may search for benefits from flexibility on moving to the job shop structures.

Actually, the need is for flexible processes to permit rapid low cost switching from one product line to another. This is possible with flexible workers whose multiple skills would develop the ability to switch easily from one kind of task to another.

As main resources, flexible processes and flexible workers would create flexible plants as plants which can adapt to changes in real time, using movable equipment, knockdown walls and easily accessible and re-routable utilities.

3. FMS- an example of technology and an alternative layout

The idea of an FMS was proposed in England (1960s) under the name "System 24", a flexible machining system that could operate without human operators 24 hours a day under computer control. From the beginning the emphasis was on automation rather than the "reorganization of workflow".

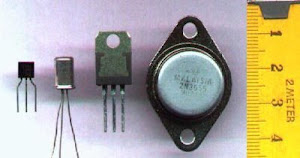

Early FMSs were large and very complex, consisting of dozens of Computer Numerical Controlled machines (CNC) and sophisticate material handling systems. They were very automated, very expensive and controlled by incredibly complex software. There were only a limited number of industries that could afford investing in a traditional FMS as described above.

Currently, the trend in FMS is toward small versions of the traditional FMS, called flexible manufacturing cells (FMC).

Today two or more CNC machines are considered a flexible cell and two ore more cells are considered a flexible manufacturing system.

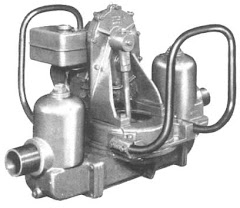

Thus, a Flexible Manufacturing System (FMS) consists of several machine tools along with part and tool handling devices such as robots, arranged so that it can handle any family of parts for which it has been designed and developed.

Different FMSs levels are:

Flexible Manufacturing Module (FMM). Example : a NC machine, a pallet changer and a part buffer;

Flexible Manufacturing (Assembly) Cell (F(M/A)C). Example : Four FMMs and an AGV(automated guided vehicle);

Flexible Manufacturing Group (FMG). Example : Two FMCs, a FMM and two AGVs which will transport parts from a Part Loading area, through machines, to a Part Unloading Area;

Flexible Production Systems (FPS). Example : A FMG and a FAC, two AGVs, an Automated Tool Storage, and an Automated Part/assembly Storage;

Flexible Manufacturing Line (FML). Example : multiple stations in a line layout and AGVs.

4. Advantages and disadvantages of FMSs implementation

Advantages

Faster, lower- cost changes from one part to another which will improve capital utilization

Lower direct labor cost, due to the reduction in number of workers

Reduced inventory, due to the planning and programming precision

Consistent and better quality, due to the automated control

Lower cost/unit of output, due to the greater productivity using the same number of workers

Savings from the indirect labor, from reduced errors, rework, repairs and rejects

Disadvantages

Limited ability to adapt to changes in product or product mix (ex. machines are of limited capacity and the tooling necessary for products, even of the same family, is not always feasible in a given FMS)

Substantial pre-planning activity

Expensive, costing millions of dollars

Technological problems of exact component positioning and precise timing necessary to process a component

Sophisticated manufacturing systems

FMSs complexity and cost are reasons for their slow acceptance by industry. In most of the cases FMCs are favored.

..bmp)

..jpg)

..jpg)

.jpg)

.gif)

.jpg)

..jpg)

+Stainless+steel+elbow.bmp)

..jpg)

..jpg)

..jpg)

..jpg)

..jpg)

..jpg)

Tablestacas..gif)

.gif)

.bmp)

..jpg)

.jpg)

..jpg)

.jpg)

..jpg)

.gif)

..jpg)

+de+madera+para+vias,sin+impregnar.jpg)

..jpg)

.gif)

..jpg)

+de+oruga.jpg)

+BEL-ART.jpg)

.jpg)

..jpg)

.gif)

..bmp)

.bmp)

2 comentarios:

Really i like the way of your blog post content, its good information for us so please sharing this interesting and useful information. Always keep sharing. Thank You.

Flexible Hose Pipes Manufacturers in Faridabad

¿Aún está activo este blog?

Publicar un comentario